KMT Waterjet Products | Pumps, Cutting Heads, Abrasive Systems

KMT Products | PRECISION CUTTING PERFORMANCE FOR

SMOOTH, CLEAN CUTS

Since 1971, KMT Waterjet Systems has been a global leader in waterjet technology and water jet machinery. For decades, KMT has manufactured water jet ultra high pressure intensifier pumps (UHP) with water pressurized up to 90,000 PSI | 6.200 bar. Our products are efficient and reliable, whether is it pure water cutting heads or abrasive waterjet pumps, KMT products are easier to maintain with no effect of heat on the products being cut.

Our line of waterjet intensifier pumps, pure water only or abrasive waterjet cutting nozzles, abrasive management systems, and waterjet parts/components are integrated with OEM waterjet machines, that have been proven reliable by thousands of worldwide customers using waterjet technology. KMT water jet cutters are ideal for cutting stone, glass, ceramic tile, granite, food, textiles, rubber, and foam, along with many other solutions. From steel cutting to paper cutting, almost no other technology provides this level of precision. Water jet technology makes cutting granite and metal cutting as smooth as cutting foam.

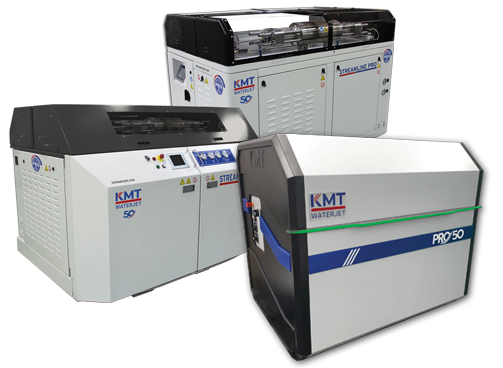

STREAMLINE PRO® 90,000 PSI | 6.200 bar PUMPS | NEW 50HP, 60HP & 125HP

KMT Waterjet Systems has launched the Future of Waterjet Technology with the introduction of the KMT Streamline PRO® 90,000 PSI | 6.200 bar Waterjet Pump.

LEARN MORE

STREAMLINE® SL-VI 60,000 PSI | 4.100 bar PUMPS | 30HP, 50HP & 100HP

KMT Waterjet STREAMLINE® SL-VI systems use the latest technology and a very smart design for ease of use, reliability and convenience.

LEARN MORE

NEO™ 60,000 PSI | 4.100 bar PUMPS | 50HP

The NEW KMT Waterjet NEO pump incorporates over 50 years of experience offering unparalleled waterjet cutting technological achievements.

LEARN MORE

TRILINE® 55,000 PSI | 3.800 bar Direct Drive Pump

Economical and Efficient Cutting!

The TRILINE® pump has an excellent cost of ownership value and can be used as a stand-alone unit for everyday cutting needs.

LEARN MORE