THE RIGHT PUMP MATTERS

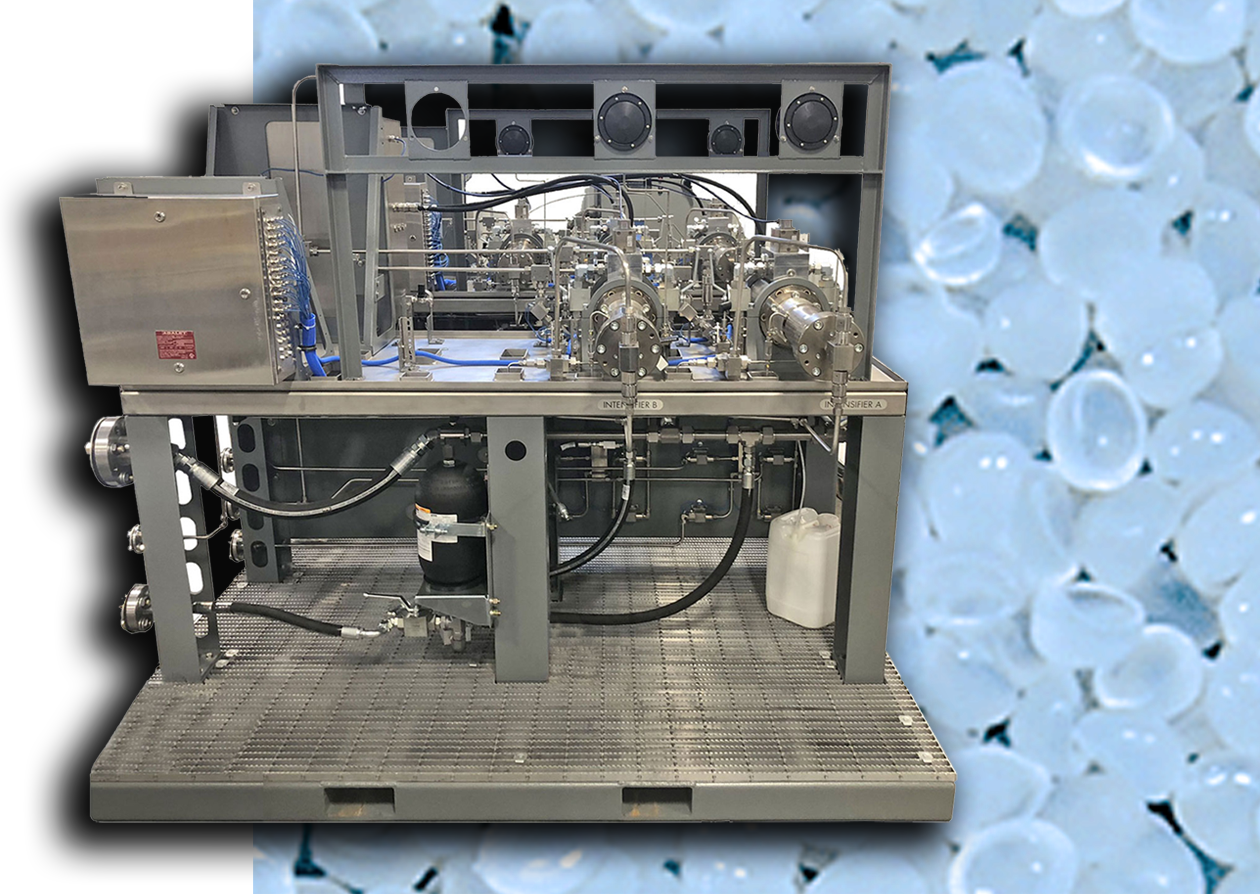

STREAMLINE PRO® 90,000 PSI PUMPS

Available in 125 HP, 60 HP and 50 HP

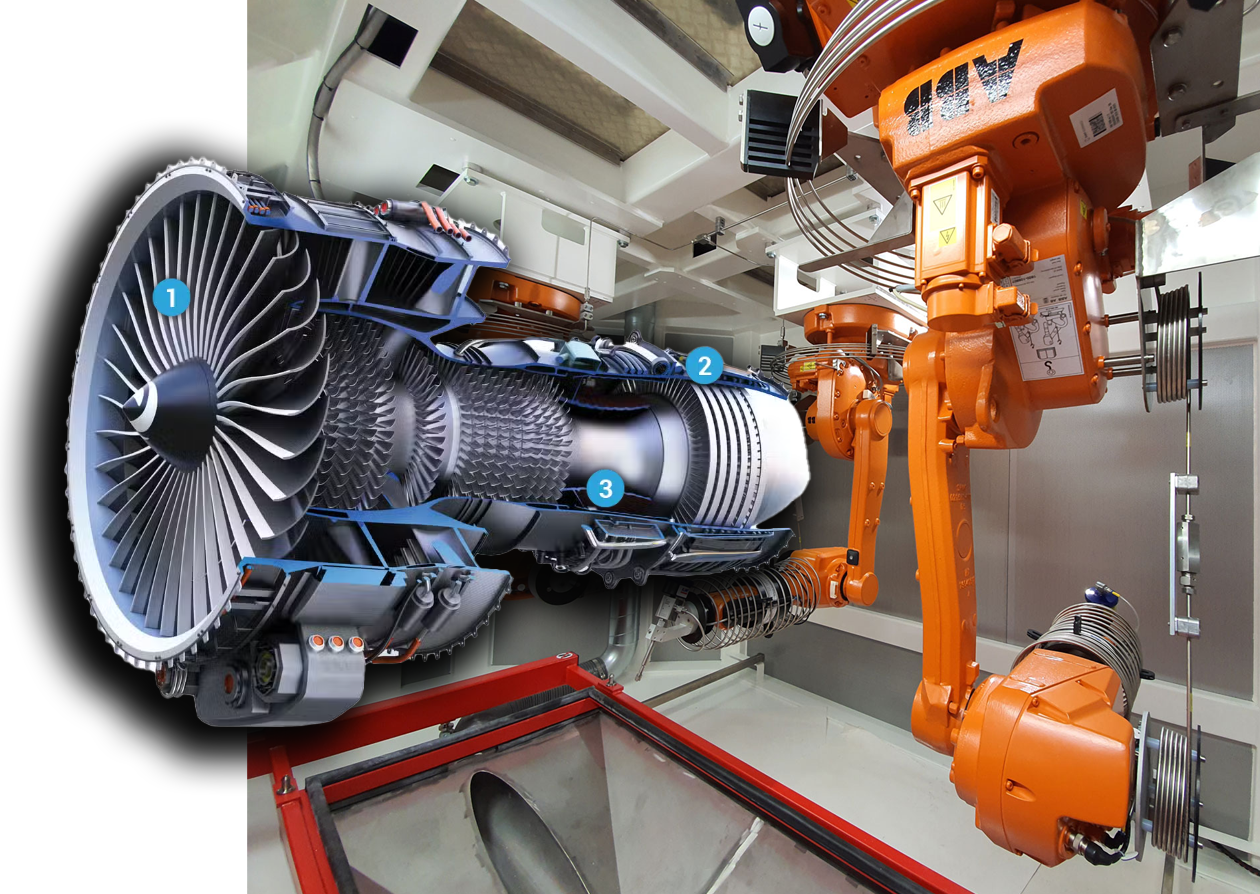

WORLD’S FASTEST WATERJET

STREAMLINE® SL-VI 60,000 PSI PUMPS

Available in 200 HP, 100 HP, 50 HP and 15 HP

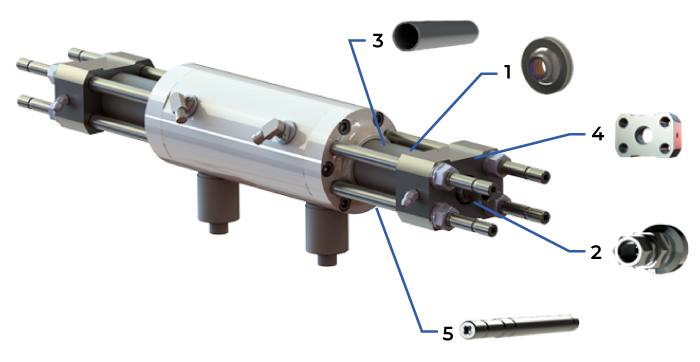

THE INDUSTRY WORKHORSE

STREAMLINE® CLASSIC 60,000 PSI 50 HP PUMP

NEO 60,000 PSI PUMP – Available in 30 HP & 50 HP

TRILINE DIRECT DRIVE 55,000 PSI 30 HP PUMP

KMT WATERJET. The pioneers of waterjet technology

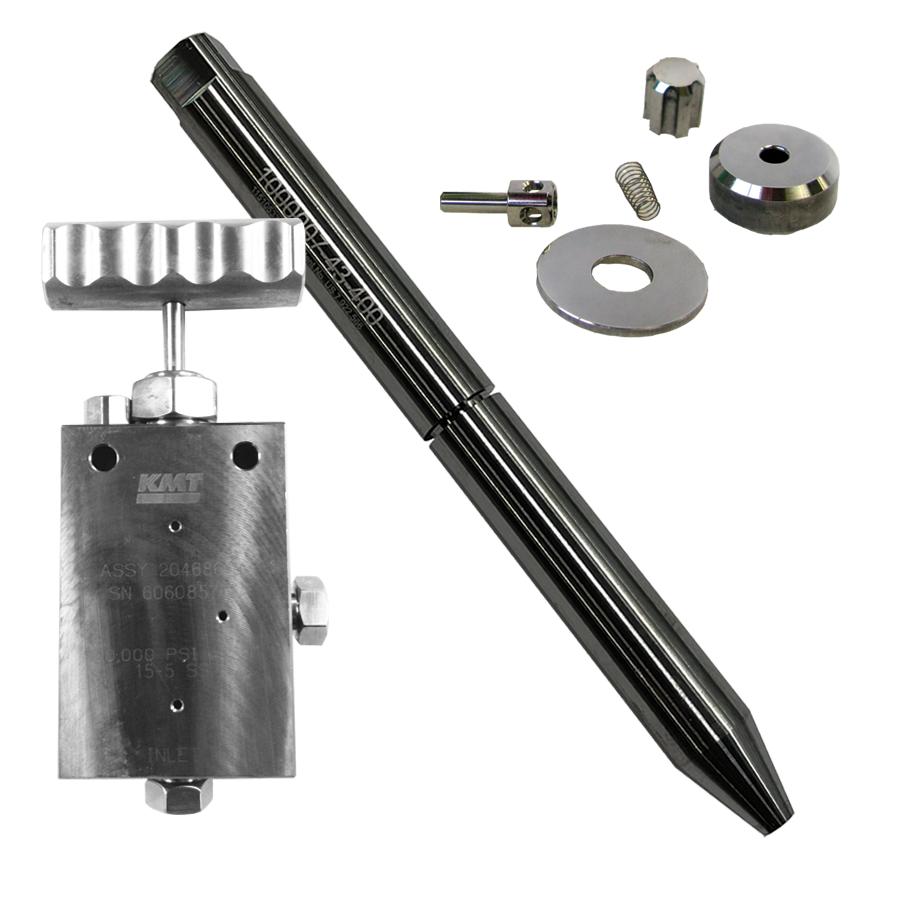

Precision Engineering

Manufactured to stringent specifications and quality standards.

specifications and quality standards.

Using Genuine KMT parts and components ensures optimal performance, reliability, and accuracy in waterjet cutting processes.

Durability and Longevity

KMT Waterjet pumps are engineered for durability and longevity.

engineered for durability and longevity.

Provide a longer lifespan compared to imitation pumps.

Results in reduced downtime, lower maintenance costs, and a more dependable waterjet cutting system.

Quality and Performance

Investing in KMT Waterjet genuine products reflects a commitment to quality engineering and manufacturing.

genuine products reflects a commitment to quality engineering and manufacturing.

Extends the lifespan of KMT pumps and genuine parts.

Ensures reliable performance and improved productivity in industrial applications.

Reliable Support and Safety

Imitation pumps may lack reliable support and could pose a safety risk.

reliable support and could pose a safety risk.

Users may face challenges in troubleshooting and servicing with imitation pumps.

Supported by a global network of KMT field engineers since 1971.

MOVING FORWARD

KMT Waterjet emphasizes the importance of choosing the right waterjet pump.

importance of choosing the right waterjet pump.

Genuine KMT products offer unmatched reliability, durability, and support.

Investing in KMT Waterjet ensures optimal performance and long-term value for industrial applications.

KMT MISSION, VISION & VALUES STATEMENT >

KMT Waterjet. The Right Waterjet Pump Really Matters.

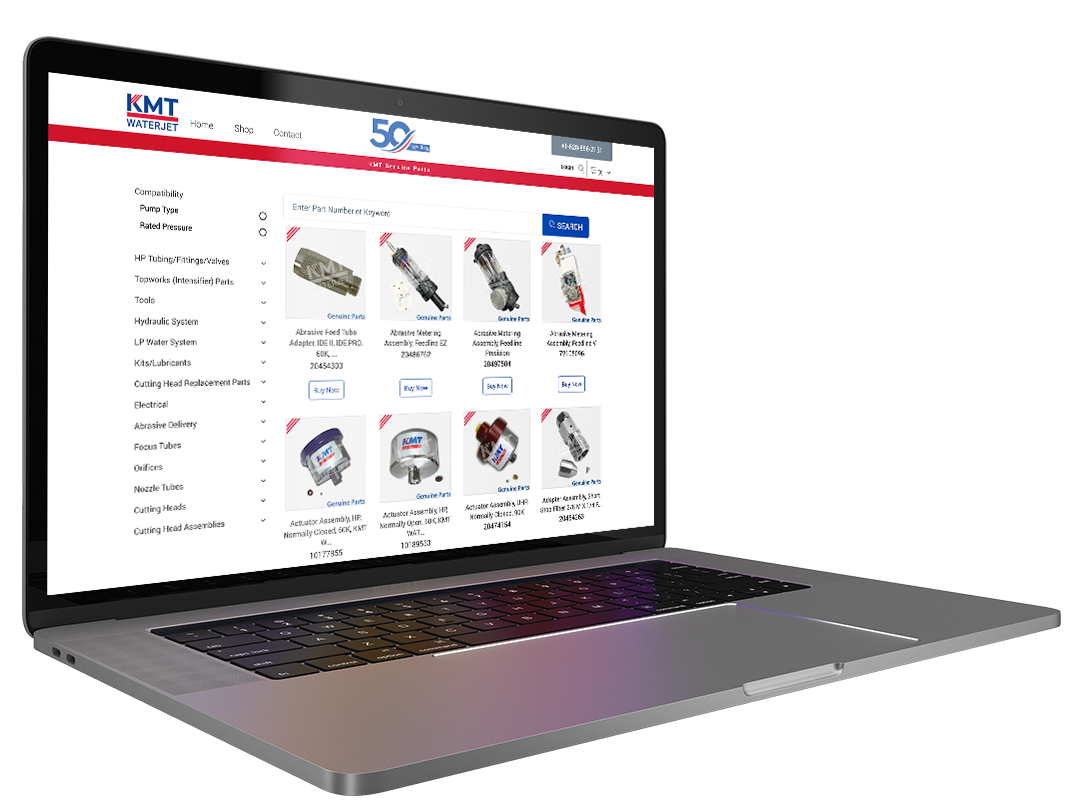

Order KMT Genuine Parts Online

Get the OEM parts you need, on demand. KMT is a world-class manufacturing facility with ISO 9001 certification. Our parts are guaranteed to be of the highest quality, ensuring that your investment is protected.

RECENT KMT WATERJET BLOG POSTS

3 Mistakes People Make Waterjet Cutting Stone

Waterjet cutting is a precise and versatile method for cutting stone, but...

Read MorePRESSURE MATTERS-THE TRUTH ABOUT HIGHER PRESSURE WATERJET CUTTING

How pressure affects cutting speed, kerf width, and abrasive use. Over the...

Read MoreWater Jet Sweden – 2005 Waterjet Machine Upgrade

OLD WATERJET MACHINE UPDATED TO ADVANCED CUTTING TECHNOLOGY Old waterjet machine updated...

Read More