Abrasive Systems & Accessories

Abrasive & Abrasive Supply Systems for Waterjet Cutting

PRECISION CUTTING PERFORMANCE FOR SMOOTH, CLEAN CUTS!

Abrasive supply systems control the entire supply chain for abrasive in waterjet cutting machines. The abrasive consumption is a key cost factor in the operation of a waterjet cutting unit. By controlling all system parameters, the cutting results can be optimized and the consumption of abrasive can be reduced. Waterjet cutting thus becomes even more cost-efficient. This is particularly the case where brittle materials such as stone, marble and glass are cut, as the uniform and constant supply of abrasive caters for fast processing without damage at low costs.

Abrasive systems for waterjet cutting normally contain the following three components:

• Abrasive metering system (Feedline)

• Abrasive bulk transfer system (ABRALINE)

• Abrasive cutting heads

ABRALINE Abrasive Delivery Systems

KMT Waterjet Systems ABRALINE Delivery Systems for abrasive flow monitoring saves time and costs.

LEARN MORE

Feedline | Abrasive Metering System

Optimized abrasive consumption for customized applications.

LEARN MORE

AMS Abrasive Management System

The integrated solution for automated waterjet cutting.

LEARN MORE

Kerf-Jet Garnet Abrasive | Shape Mined Material

High efficiency garnet for high efficiency cutting.

LEARN MORE

Reliable Accessories for High Pressure Waterjet Cutting Machines

KMT High Pressure pumps for waterjet cutting are built for the best possible reliability as well as simple and quick maintenance. Yet even the best product can be made more efficient or easier to maintain if you use intelligent accessories to support the pumps performance. Ranging from systems for a constant and steady cutting water supply to installations which allow for the maximum efficiency of your pump network to desludging systems for cleaning cutting basins of abrasive cutting systems.

HIGH PRESSURE ACCESSORIES:

• CLEANLINE I

• STROKE CONTROL

• BOOSTERLINE

CLEANLINE I - Mobile Desludging System

CLEANLINE I is the mobile desludging system for cutting basins of waterjet cutting systems. The easy-to-use system saves its users the effort of laborious manual basin cleaning, the need for expensive suction services, or the occurrence of long production stoppages

FEATURES:

-

Mobility: practical for workshops with more than one cutting table

-

Removal of 3-4 m³ of abrasive sludge per hour

-

Simultaneous extracting of sludge and jetting back of filtered water

-

Pneumatically driven diaphragm pumps for handling aggressive, abrasive and viscous liquids

-

Minimal maintenance thanks to high quality components

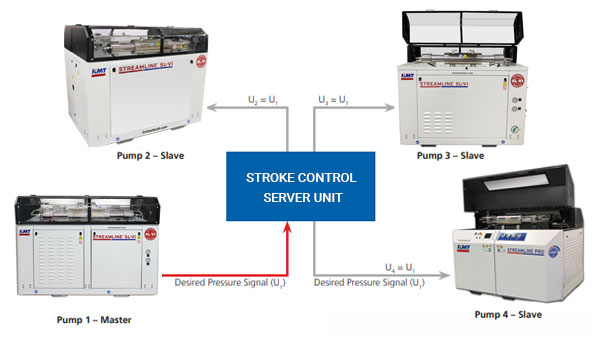

Pump Networking with STROKE CONTROL

Load Balancing with Stroke Control

Additional production volumes often require an expansion of pump capacity. As an alternative to the purchase of larger pumps, the load balancing stroke control system allows for an interlinking and efficient operation of many STREAMLINE pumps in a pump network. Especially production facilities with multiple high pressure pumps and cutting stations working in an independent fashion can benefit of the many advantages of such a pump network.

BENEFITS:- Easy operation

- Easy increase and reduction of the number of connected pumps

- Possibility to connect pumps of different power and capacity

- Only a yearly calibration is necessary to maintain the system

- Any pumps can be used with any table

- PLC balancing proportional hydraulic control

- Overstroke and safety systems are not affected

BOOSTERLINE I Cutting Water Supply System

Consistent & Constant Water Pressure

The steady cutting water supply of high pressure pumps is a significant factor when it comes to the reliability and economic efficiency of a waterjet cutting machine. The BOOSTERLINE cutting water supply system is KMT‘s innovative solution to guarantee a constant inlet pressure of the cutting water for ultra-high pressure pumps.

BENEFITS:- Constant pressure ensures safety of production.

- The constant supply of water to the ultra-high pressure pump through the BOOSTERLINE system prolongs the service life of wear parts in the intensifier. The maintenance interval of the intensifier and the downtimes of the cutting unit are reduced as the high pressure pump is operated at ideal conditions.

- High pressure pumps should be operated at a constant inlet pressure of 3.5 bar. Where pressure fluctuations occur in the public water supply, the BOOSTERLINE water supply system guarantees a steady volume flow to the high pressure pump. The system is automatically switched on and off, depending whether the intensifier is activated or not. Thanks to the fully automated operation, the BOOSTERLINE is very easy to operate.